Vasculature

The digitally fabricated sculpture utilizes robotic grinding to carve biomimetic lattice structures inspired by the Victoria amazonica lily, generated via structured shortest-path algorithms, highlighting innovation in computational design and robotic craft.selected exhibition

- Design is Human, Isola Design Festival, Milan Design Week, Italy. 2025.04.07–2025.04.13

Artwork Description/

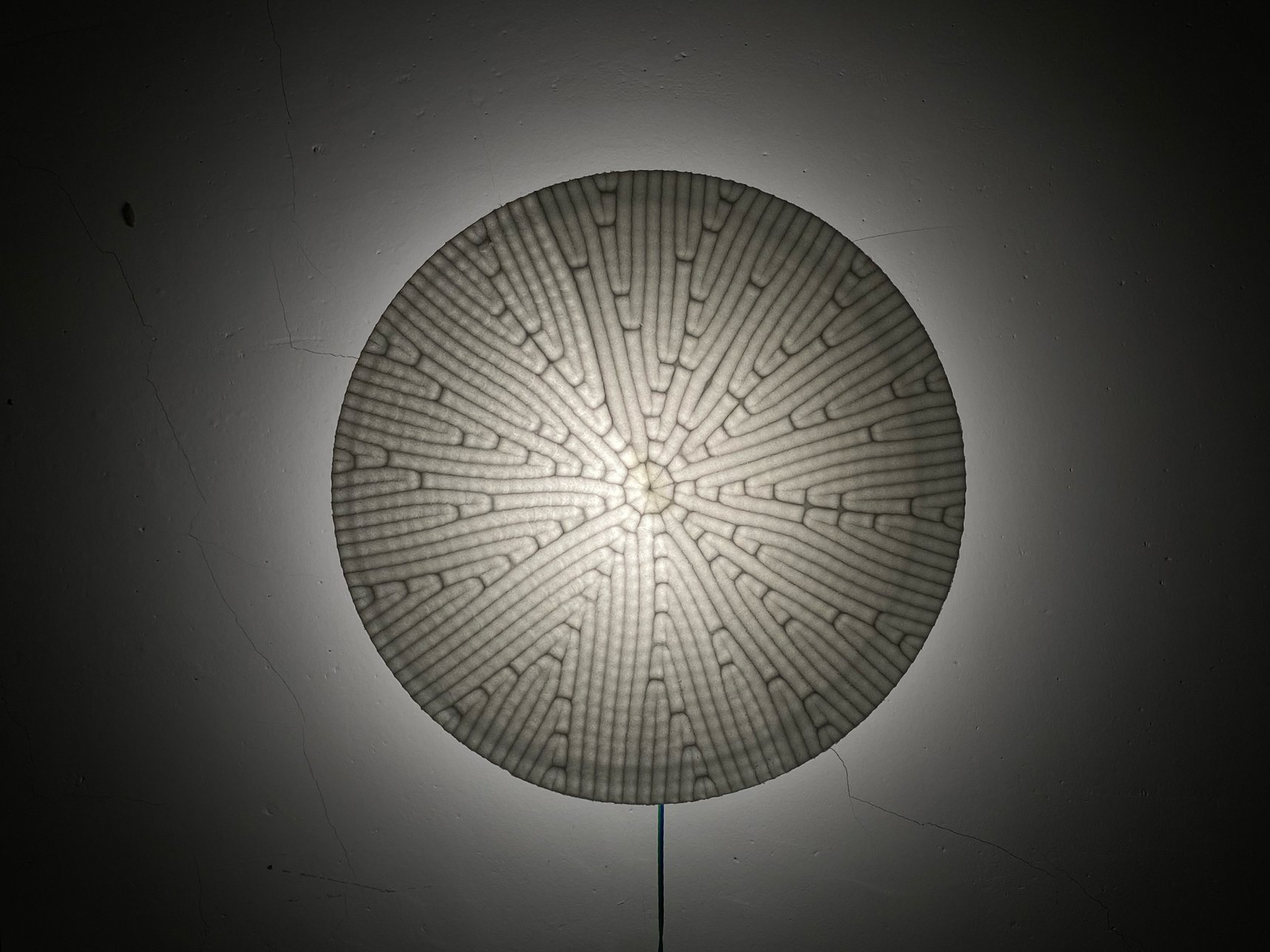

This digitally fabricated sculpture utilizes robotic subtractive fabrication techniques, specifically robotic grinding, to carve intricate biomimetic lattice structures from high-density foam. Its geometric form is generated through parametric and algorithmic design processes using structured shortest-path algorithms to mimic the efficiency and systematic regularity found in natural branching patterns, inspired by the radial vascular structure of the giant Amazonian water lily (Victoria amazonica). Employing a double-sided carving method, the resulting translucent patterns vividly emerge in both direct light and shadow.

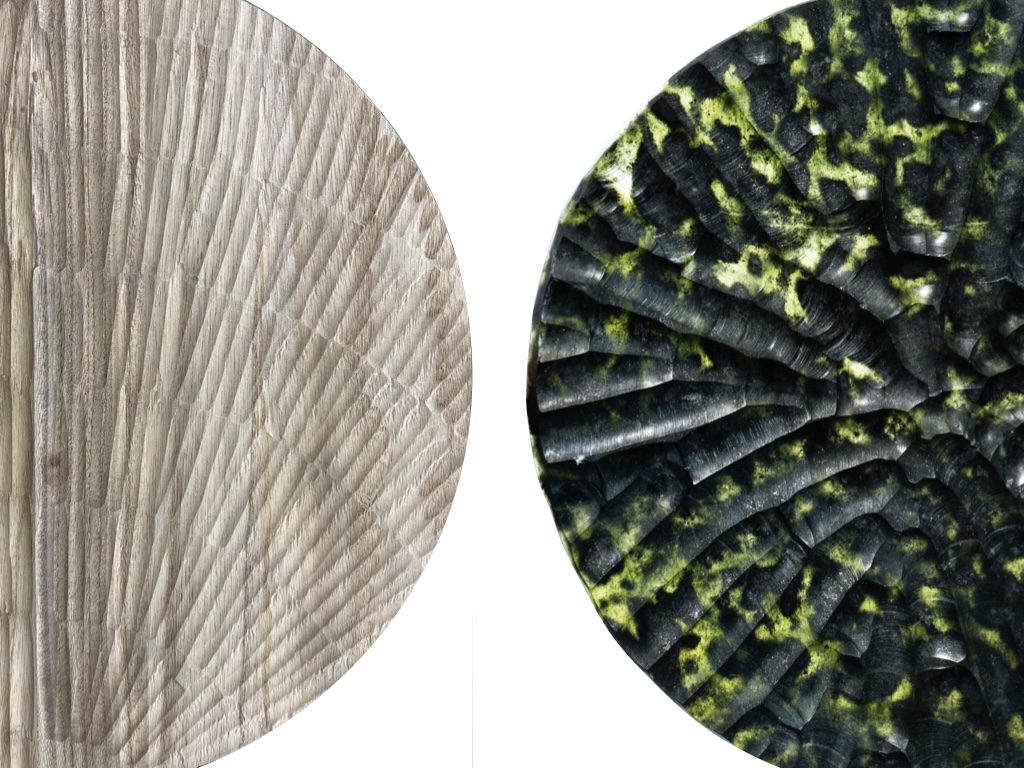

This artwork introduces a novel formal language by abstracting biological branching patterns into sculptural expressions. Although currently executed in foam, this subtractive fabrication technique is adaptable to materials such as jade, glass, and wood, illustrating significant potential for hybrid digital and traditional aesthetic exploration. The work highlights innovation in computational design, biomimicry, and robotic fabrication, emphasizing material investigation.

Technical Description/

This artwork employs robotic subtractive fabrication techniques, particularly robotic grinding, integrating computational geometry and biomimicry principles to reinterpret the vascular patterns of the Victoria amazonica lily pad. The artist uses Rhino/Grasshopper software to apply structured shortest-path algorithms, conceptually referencing biological efficiency and systematic regularity, generating parametric geometric models. These digital models are then systematically translated into precise Tool Center Point (TCP) paths via a custom-developed KUKA TACO robotic programming interface.

A KUKA industrial robotic arm equipped with specialized grinding tools executes these calculated TCP paths on both sides of high-density foam, crafting complex biomimetic lattice textures. The carefully designed double-sided grinding process accurately manages material removal and surface texture details, resulting in compelling translucent lattice patterns enhanced by dynamic interplay of light and shadow, significantly enriching visual spatial depth.

During fabrication, computational feedback loops actively manage robotic grinding parameters, including spindle speed, feed rate, and grinding depth, ensuring optimal tool performance and material integrity. This rigorous digital-to-physical process accurately translates complex, organically inspired geometric structures into physical forms, exemplifying the integration of digital precision and robotic craftsmanship.

Importantly, this grinding-based subtractive fabrication method demonstrates significant adaptability and scalability, evidenced by ongoing experiments applying robotic grinding techniques to materials such as jade, cold-worked glass, and wood chiseling. These advanced fabrication strategies foster innovative combinations of digital fabrication and traditional craftsmanship, paving the way for new material and formal experiments within computational design and robotic manufacturing.

Artist/Design Lead: Scottie Chih-Chieh Huang

with Collaborators:

Shih-Yuan Wang (Core Robotic Tech Developer)

Ming-Hong Wu (Customized LED Panel Developer)

and BioLogicDesign Team: Deng-Feng Jiang, Jie-Ke Pan

See more further application in Jade Grinding and Wood Carving

---

創作概述 /

此數位雕塑作品透過機械手臂減材製造技術,特別是機械研磨,以高密度保麗龍雕刻出複雜的仿生晶格紋理。其幾何形態經由參數化及演算法設計流程,以結構化最短路徑演算法模擬自然界生物分支紋理的高效率與規律性,靈感來自亞馬遜巨型王蓮(Victoria amazonica)的放射狀葉脈結構。作品採用雙面雕刻技術,形成半透明的晶格紋理,在光影互動下清晰呈現。

此作品展現嶄新的造形語言,透過將生物分枝規則抽象化後轉譯為雕塑形式。雖然目前使用的是保麗龍,此減材製造技術亦可延伸至玉石、玻璃及木材等材質,探索數位與傳統美學融合的可能性。作品強調運算設計、仿生學與機械製造的創新。

技術內容 /

此作品使用機械手臂減材製造技術,尤其是機械研磨,結合運算幾何與仿生原理,重新詮釋維多莉亞亞馬遜王蓮的葉脈紋理。藝術家以 Rhino/Grasshopper 軟體應用結構化的最短路徑演算法,概念性地參考生物的高效率與規律性,產生參數化幾何模型,再透過自行開發的 KUKA TACO 機械手臂介面轉譯為精確的TCP路徑。

製作過程中,KUKA工業機械手臂搭配特製研磨工具,精確執行雙面研磨,以雕刻出複雜的仿生晶格紋理。此製程控制材料移除量與表面紋理細節,產生動態光影互動的半透明晶格,提升視覺深度。

製作過程中透過即時回饋系統調控研磨參數,包括主軸轉速、進給速度及研磨深度,確保工具性能與材料完整性。此數位到實體的流程準確轉譯複雜的幾何形態,展現數位精準度與機械工藝的融合。

此基於研磨的減材製造方法具適應性與延展性,目前實驗將技術延伸至玉石、玻璃與木材等材質,促進數位製造與傳統工藝的創新融合,推動運算設計與機械製造的新可能。

All images and videos courtesy Scottie Chih-Chieh Huang.